A Dedicated Team with Great Knowledge & People who Solve Problems

Emeg’s overriding objective and mission statement is to offer ‘the highest quality range of one-stop maintenance services’ where work undertaken is not too small or too large, with a particular focus on the individual needs and expectations of train operators within their rail depot facilities.

Emeg has a highly experienced in-house staff based in Chesterfield & Manchester that offer positive turnkey resolutions or alternative design options to increase equipment effectiveness to drive the key operational efficiencies being sought in a very demanding industry, whether electrical, mechanical or civils-based.

Emeg offers pre-planned standard or bespoke planned and reactive maintenance regimes covering all depot systems, such as carriage wash machines, controlled emission toilet systems, water, oil & coolant systems, fuelling solutions, AdBlue fluid mixing, sanding systems, air purification & ventilation, shore supplies, and depot protection equipment – not to exclude the internal depot engineering functions such as electrical jacks, automatic doors, gantry cranes and the like.

How We Operate

Emeg’s maintenance teams operate within a paperless environment where all Planned Preventative Maintenance (PPM), reactive call-out and job sheet documentation is online with copies sent direct to the client if required.

Emeg has a customer service centre which is available with engineers on rota to respond 24/7, 365. Emeg’s customer service base is extensive and they expect and receive total professionalism and flexibility of working hours with honest appraisals. We always accept full responsibility and accountability for our actions.

Some of Emeg’s customers with which we have full maintenance contracts are Network Rail, Great Western Railway, Alstom, Bombardier, South Eastern Trains, Arriva Traincare, Northern Rail and Midland Metro, to name but a few.

Maintenance Case Studies

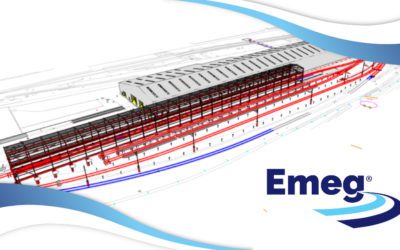

Emeg® Group Awarded Etches Park Depot Improvement Contract

Emeg® Group is pleased to announce that we were recently appointed by Buckingham Group Contracting to undertake a comprehensive schedule of improvement work at the Etches Park rail depot in Derby for East Midlands Railway. This vital upgrade work is necessary ahead of...

Fuelling Facility – Croft Street, Preston Depot

The Northern Hub programme was developed to increase capacity, line speed and connectivity throughout the North West of England. Croft Street Depot, Preston is one of the Network Rail owned depots to be upgraded and have a new fuelling system installed.

Northern Hub Electrification – Allerton Depot

Allerton is one of the four Network Rail owned depots to be upgraded and have OLE reinstated in order to facilitate the maintenance of the additional electric rolling stock.

Leyland Carriage Sidings

Leyland Carriage sidings is one of the four Network Rail owned depots to be upgraded in order to facilitate the maintenance and servicing of the additional rolling stock.